| hey-produkte-getriebemotoren-titel |

Gear motors

with planetary-, spur gear, bevel angle or worm gear

| hey-produkte-getriebemotoren-reihe-g2 |

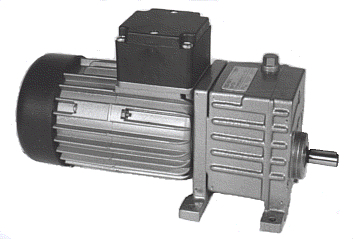

Geared Motors Series G2

with asynchronous motors and fixed speed

The mini gearboxes designed for industrial purposes

Series G2 are particularly characterized by their small design.

In sturdy cast aluminum housings, hardened and partially flank-ground gears are used, which guarantees a very high level of service life and smoothness.

- Executions

with free input shaft

with 3-phase motor 0.03 kW 230/400 V 50 Hz

with 3-phase motor 0.09 kW 230/400 V 50 Hz - suitable for operation with frequency converter - Output torques T2 up to 30 Nm

- Ratios i= 2,96 up to 5611

- Available in foot and flange versions

Mountings B3 - B14 - B5 - B3/B14 - B3/B5 - All gear motors can be used in any position

- Small compact design

- Combination with helical, helical-bevel or worm gears

- Lubricated for life, therefore maintenance-free

| hey-produkte-getriebemotoren-reihe-gn2 |

Geared Motors Series GN

with direct current shunt motor, speed adjustable

The mini gearboxes of the Series GN, designed for industrial purposes, are particularly characterized by their small design.

In sturdy cast aluminum housings, hardened and partially flank-ground gears are used, which guarantees a very high level of service life and smoothness.

Use of self-cooled, low-maintenance direct current shunt motors with ball-bearing armature. With an AC voltage tachometer generator and thyristor controller, a control range of up to R = 50 is possible.

- Drive power P= 0,150 kW

- Output torques T2 up to 30 Nm

- Translations of i=3,33 to i=5611

- Available in foot and flange versions

Mountings B3 - B14 - B5 - B3/B14 - B3/B5 - All gear motors can be used in any position

- Small compact design

- Combination with helical, helical-bevel or worm gears

- Lubricated for life, therefore maintenance-free

| hey-produkte-getriebemotoren-reihe-gf2 |

Geared Motors Series GF2

with integrated frequency converter, speed adjustable

The series GF2 mini gearboxes, designed for industrial purposes, are particularly characterized by their small and compact design. Tempered gear wheels are used in stable cast aluminum housings, which guarantees a very high level of service life and smoothness.

The large number of different gear ratios enables a fine gradation of the speed range.

With the high-quality frequency converter integrated in the motor terminal box, a potentiometer can be used as standard to set an adjustment range of 1: 6 and, with a built-in external fan, up to 1: 20.

A remote control can also be supplied as an option, so that the drive can also be conveniently controlled in hard-to-reach places.

- Drive power P= 0.09 kW

- Output torques T2 up to 30 Nm

- Gear ratios from i=2.96 to i=5611

- Available in foot and flange versions

- Designs B3 - B14 - B5 - B3/B14 - B3/B5

- All geared motors can be used in any position

- Small compact design

- Combination with spur, spur-bevel or worm gears

- Lubricated for life, therefore maintenance-free

- High standard

- Standard integration of radio interference suppression filter class A, optional class B

- RS 485 interface

- DC link chokes

- PID controller

- Easy commissioning

- Motor and frequency converter as a complete unit

- Optimum tuning of the frequency converter to the data of the basic motor

- Time savings and exclusion of possible causes of error during commissioning

- No shielded motor leads

- For reasons of electromagnetic compatibility, no shielded cables are required for separately installed converters

- Reduction of the laying effort and the range of cables to be kept available

- Energy saving

- Use of standard motors with efficiencies according to classification eff 2 or eff 1 of the CEMEP agreement

- Optimum speed adjustment of the compact drives to the process

- After a very short time, the additional price of a compact drive compared to a standard drive is amortized by saving energy costs

- High level of quality

- Robust design and protection class IP55 for all components of the drive

- Encapsulation of all sensitive components of the converter to ensure the vibration resistance of the converter part in the compact drive